- Easy Rotation on the tube axis prior to welding to accommodate any nozzle orientation.

- No Brittle or deformed threads due to overheating of the riser material during welding.

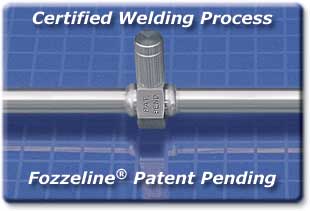

- The fit and finish of the product reveals the quality that is designed into it.

- Up to six nozzle ports can be drilled on each nozzle fixture.

- The certified welding process is completed while maintaining the metallurgical and structural properties of the stainless steel stock.

- No nozzle clogging due to dislodged residual burnt metal and sugaring within the tube. This occurs under high pressure as a by product of the hand welding process.

- Easy nozzle orientation during installation due to the flat sides of the nozzle ports.

- Tube Material: Stainless steel 316L welded, .375" O.D. with a wall thickness of .035".

- Minimum Theoretical Burst Pressure: @-20° F to 100°F 14,000 PSI.

- Minimum Working Pressure: @-20°F to 100°F 3,500 PSI.

- Minimum Tensile Strength: @-20°F to 100°F 70,000 PSI.

- Nozzle Fixture: CNC machined from solid 316L stainless steel hex material. Port thread pattern is 12/24.

- Welds are Orbital G.T.A.W. Fusion. Weld strength exceeds that of original material.

- All lines are inspected and pressure tested prior to shipment.

- Orbital welding procedures are certified to the requirements of ASME Sec.IX Boiler and Pressure Vessel Code/ASME B31.1 & B31.3 Piping Codes.